Maintenance: reactive, preventive or predictive?

Novotema's maintenance technicians manage the three of them: let's see why.

Maintenance: reactive, preventive or predictive?

Novotema's maintenance technicians manage the three of them: let's see why.

It's pretty easy to understand the reason why you need to be ready to deal with any sudden breakdowns! Our colleagues at the maintenance department are always on alert, ready to receive reports from production and come to rescue in real time to solve any malfunctions that could compromise the correct production cycle of our gaskets.

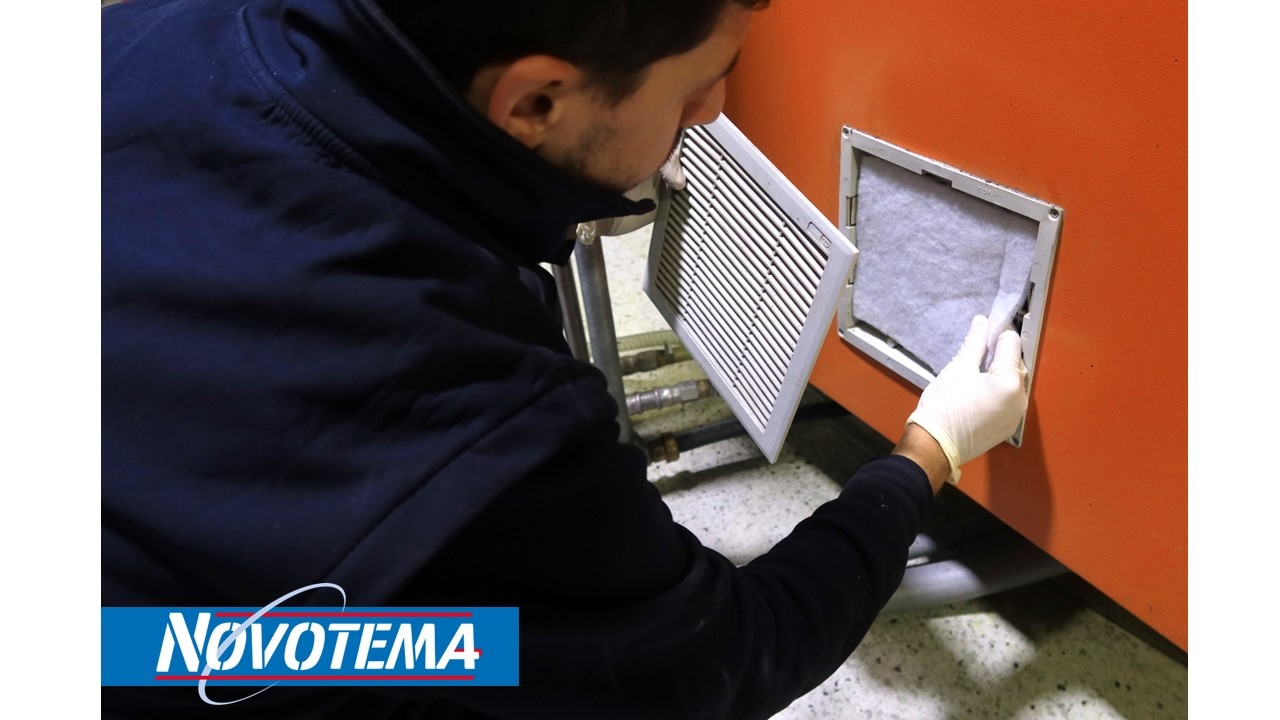

Correct preventive maintenance, however, if duly organized and managed, allows better work planning, enables a more radical resolution of problems and also a consequent saving of time, as well as better production efficiency and improved quality.

The third model of maintenance is the so called “predictive maintenance”.

As far as at Novotema we always try to run the extra mile to improve our processes and performance, we implemented this third type of maintenance as well. In practice, this approach involves the in-depth analysis of parameters and tools, through monitoring systems, to estimate with good accuracy the moment when they will have to be replaced.

To make a long story short: at Novotema we try to do our best to go further and keep improving our processes and our products.